Ferrari 512 BBi Restomod

/Model: 1981 Ferrari 512BB Boxer

Engine Specs:

399 lb-ft of torque @5100-rpm, 471-hp @7000-rpm

Click here to see details and dyno sheet on this motor.

Type: Flat-12, 512BB

Bore: 82mm Razzo Rosso forged pistons

Stroke: 78mm

Compression ratio: 10:1

Cylinder heads: intake ported and tested on flow bench, intake and exhaust manifolds matched

Camshafts: 246-degrees at .050", intake and exhaust, 9.1mm lift

Induction: Weber 40IF3C, 3-barrel carburetors, 32mm venturis

Exhaust: standard Ferrari headers, port matched and ceramic coated

Ignition: Stock Ferrari electronic ignition, new plug wires, BP7ES plugs

Suspension and Brakes:

Suspension: stock Konis revalved and converted to threaded-body coilovers, Eibach racing springs

Brakes: rebuilt with cross-drilled rotors

Wheels and Tires:

Wheels: 17x8-inch front and 17x10-inch rear Razzo Rosso wheels

Tires: 235/50-17 and 255/45-17 Pirelli P-Zero

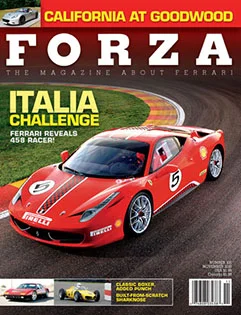

Click below to read Forza'a article on this upgraded Ferrari 512.

More information on this 512BB:

The owner of this 512BB searched for almost 2 years to find the ideal subject for this project. He had been a fan of the Boxer design since the 1970's and had promised himself that one day, he would own one. Finally, through the help of a Ferrari broker, a clean, low mileage 512BB was located in Northern California and purchased. This particular Boxer was unmolested by "converters" and was virtually a full-on Euro model.

What started out as an engine-out service soon escalated into an all-out restomod project. To quote the owner, "I knew that after communicating with Tate over a couple of years time and seeing various articles in FORZA magazine about the various cars they had done, that it was a pretty good bet that CAROBU could do what I wanted. We would talk about the pros and cons of various modifications/restoration levels and I would ultimately say 'let's do it!'."

A big focus of this project was extracting more power from the 5 liter 12 cylinder Boxer engine so that it wouldn't be embarrassed by more modern sports cars while still maintaining the a stock engine look. Again the owner's perspective, "I drove 3 different 512BBis and was disappointed that they lacked the 'kick-in-the-butt' performance I had expected." Then he drove a carbureted 512BB and reported, "I was pleasantly surprised; it was a noticeable improvement in performance over the injected cars. I talked to Tate about my experiences of driving both models and he told me that the Weber carb'd version definitely had more 'tuning' potential. The car needed an engine-out service anyway, so I said...'what if?' and we just kept going from there."

The plan included rebuilding the engine with a "balanced" combination of parts and modifications to produce a strong yet flexible power curve combined with street reliability. The paint/bodywork needed attention too; the front spoiler was smashed and the front and rear lids had bad fits on the right side. The paint was a quickie re-spray over the original factory black color and it looked tacky with various masking errors. Additionally, the "blackout" on the rear deck and door jams was done incorrectly.

The original interior was cream colored with black accents (matching the black paint) and needed to be updated to match the red color that was going to be retained. The decision was made to with an all black interior (including the headliner) with red accent on the seats (Daytona style) and the door pocket liners.

The suspension needed a complete rebuild as the right front Koni shock was frozen solid and the rubber bushings had deteriorated badly after 25 years of use. Rebuilding the braking system was mandatory also. The original wheels were dinged up and the choice of 15" tires limited to Michelin XWX (a 30 year old design) so 17" wheels were added to the list of changes to improve the handling.

With all the plans made, we could start the work in earnest. As the owner said, "I did not want to hurry and wanted CAROBU to the amount of time necessary to do the job. The budget was important, but I didn't want it to be something that tied our hands. It was a situation of 'if it's worth doing, it's worth doing right'."

The Engine Work

Before any modifications were finalized, the critical engine dimensions were measured and incorporated into an engine model for dyno simulation purposes. The most critical aspect of an engine, when it comes making power, is the efficiency and balance of the intake and exhaust port flows coupled with a complimentary camshaft design.

Cylinder Head and Camshafts

The first step in cylinder head modification is to establish the weak aspect of port flow. We test the heads on a Superflow SF600 flow bench that is computerized with a FlowCom attachment and fed into Performance Trends Flow Analyzer software. Most 2-valve Ferrari heads are intake flow deficient. In the case of the 512BB, the original intake port flows 160 cfm @ 28" and .350" of valve lift. At the same point, the exhaust port flows 125 cfm. Our calculations from our engine simulation software showed that an intake port with 180 cfm would improve power while keeping the torque curve needed for decent street performance.

The necessary porting work was done to the intake side and the intake manifolds were matched to the new port dimensions. We left the exhaust port stock, but used new sodium cooled exhaust valves from Zanzi in Italy. As a side-note, sodium cooled exhaust valves get a bad reputation in the Ferrari service business due to valve breakage. Sodium filled valves were made in the old days by welding the valve head onto the hollow stem. After 25-30 years of hot/cold cycles, the exhaust valves (this applies to 308, Daytona and Boxers) had a bad habit of breaking off the head which then embedded itself into the top of the piston; usually at high rpm. The result wasn't pretty. Modern designs use a one piece hollow stem valve so that the head doesn't fall off. As Ferrari designed the Boxer engine with sodium cooled exhaust valves for better cooling, we recommend putting new ones in during a rebuild and not using aftermarket stainless valves without sodium cooling. Granted, there is a price difference, but since we were planning on generating more heat in the engine (by making more power), it is a worth while cost.

Once the port flow numbers are finalized, they can be plugged into the engine simulation program. The camshaft profile can now be designed to take maximum advantage of the flow increase. The goal was good mid-range torque and top end power with street driveability. As it turned out, our 'Daytona' cam profiles tested well in the simulation. With 247º of duration @ .050" and a total lift of .363" (9.1mm) on both the intake and exhaust lobes, this would fulfill all of our goals. This profile would also allow the use of stock Ferrari valve springs (new ones were used). Later dyno tests would confirm the engine simulation work.

Engine Block

The standard 512BB bore/stroke dimensions are 82mm x 78mm yielding just under 5 liter of displacement. We didn't plan to make any big increases in engine size so the original cast iron liners were over-bored 0.5mm to give a fresh surface for the new Razzo Rosso forged pistons (10.2:1 C.R.). The original crankshaft was cleaned out, magnafluxed and balanced. The connecting rods were inspected, magnafluxed and rebuilt using new Razzo Rosso specification rod bolts and nuts. The basic 512BB bottom end is very strong so no additional modifications were needed.

Exhaust System

The standard Ferrari exhaust headers were retained and port matched to head. Ceramic coating was applied to keep the heat in and the rust out. To compliment the headers, a new polished stainless steel Tubi sport muffler system was installed. The light weight (over 40 lbs. less) Tubi bolted right on and sounds great!

Dyno Testing

After the engine build was finished, the dyno break-in and power testing/tuning begins. The engine started easily and ran the low speed break-in cycle without a hitch. Dual oxygen sensors were installed (one for each bank) so that the Weber carbs could be dialed in. As predicted, richer jetting was necessary to realize the maximum power numbers (see dyno test). The end result was almost 400 lb ft of torque with over 375 lb ft available from 4,000 to 6,500 rpm - perfect for strong street driving! Maximum power at 7,000 rpm was 470 HP. This is a 100+ HP gain over the standard engine. We achieved our goals and verified all of the engine simulation and design work.