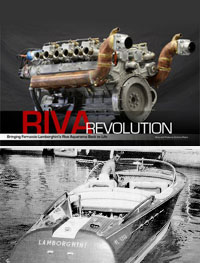

Riva Lamborghini Boat Project

/Riva Lamborghini Boat Engine Project

Riva and Lamborghini are two iconic Italian names that need no introduction. Carlo Riva and Ferruccio Lamborghini were both at the top of their game in 1968 when Ferruccio ordered a new Riva Aquarama speedboat. This unique Aquarama was fitted with a pair of Lamborghini 4.0L V12's that were modified for marine use by the Lamborghini factory. Riva custom designed and built the exhaust system with open pipes according to Lamborghini's request. After all of the work to install the Lamborghini engines into the Riva, the final performance was disappointing. The high-revving 4.0L engines were not ideally suited to marine use with the torque peak coming at 5,000 rpm. Marine engines, like the 320 HP big block Riva-Crusader V-8 engines that normally would have resided in the Aquarama's engine bay, make maximum torque at low rpm; this is necessary to get the boat up to planning speed.

The goal of this project was to re-design the Lamborghini 4-cam engine to perform properly in a Marine application. The primary method used to achieve this is to increase the displacement of the engine. Adding displacement has a 2-pronged effect on the torque curve of the engine. First, a larger engine will make more torque by virtue of its size. Second, making the engine bigger while keeping the cylinder heads basically the same will lower the engine speed where peak torque occurs. The peaking speed is reduced further by changing the camshaft duration.

Before any modifications are made, the base engine parameters are inputted into our engine simulation program. In this case we modeled the 4.0L Espada engine as a baseline for the final configuration. When the baseline model was working properly, then we could start making changes that we thought might work. Bore and stroke were changed, cam timing was altered and the exhaust system was modeled. Additionally, changes were necessary to the intake flow for best results.

After the computer simulation work was done, parts needed to be designed and specified for the new configuration. A new billet crankshaft, special connecting rods, forged pistons, deck plates, longer sleeves and head studs were some of the special parts made for the engine internals. Special machine work was done to the block to accept the new parts. Much hand fitting of the parts was necessary because of the close clearances. The cylinder heads were also hand ported to achieve the proper flow characteristics suggested by the engine simulation model. The camshafts were ground to new profiles on the intake and the exhaust lobes.

During the engine assembly, changes were made to the cam drive sprockets; they were made larger in diameter to accommodate the longer cam chain length. The piston skirts needed to be clearance to add some space when opposite cylinders in the 60º V-12 engine were at the bottom of the stroke. The crankshaft counter weights had to pared-down to size to allow the pistons to clear at BDC. These are just a few of the myriad details that have to be attended to when radically modifying an engine.

Click here to see the dyno information and videos for the Riva Lamborghini V12 engines.